Benefits of Using the Right Quality Bars in Construction

Choosing the right steel bars is essential for ensuring the strength, safety, and durability of any construction project. High-quality bars provide better load-bearing capacity, helping structures withstand pressure, tension, and environmental stress over time. The correct grade of bars also improves bonding with concrete, reducing the risk of cracks and structural failure. Using the right bars enhances overall construction reliability and minimizes long-term maintenance costs. It ensures compliance with building standards, improves resistance to corrosion, and increases the lifespan of the structure. Proper bar selection ultimately plays a vital role in delivering safe, stable, and long-lasting buildings.

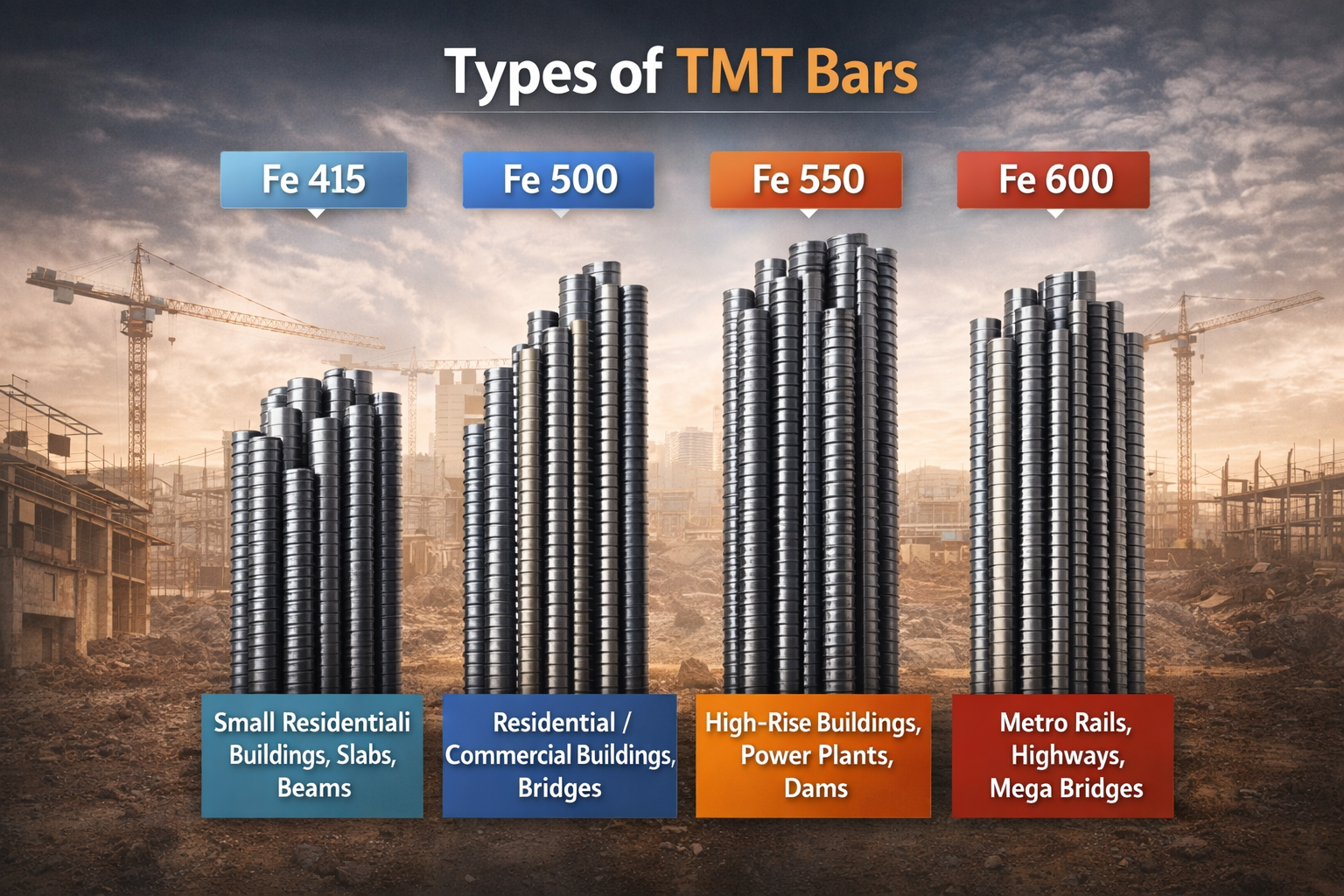

Types of Bars, Thickness & Their Uses

Fe 415 Bars

Thickness: 6 mm, 8 mm, 10 mm, 12 mm, 16 mm, 20 mm

Uses: Used in small residential buildings, slabs, beams, staircases, lintels, and light RCC works where load requirements are low to moderate.

Fe 550 Bars

Thickness: 10 mm, 12 mm, 16 mm, 20 mm, 25 mm, 32 mm

Uses: Ideal for residential and commercial buildings, foundations, columns, bridges, flyovers, and general RCC structures.

Fe 500D Bars

Thickness: 10mm, 12mm, 16mm, 20mm

Uses: Commonly used in high-rise buildings, industrial structures, power plants, dams, and large infrastructure projects.

Fe 600 Bars

Thickness: 12 mm, 16 mm, 20 mm, 25 mm, 32 mm, 40 mm

Uses: Used in metro rail projects, highways, mega bridges, offshore structures, and earthquake-resistant constructions.

Some Addtional Information

Common TMT Bar Thickness and Typical Applications

- 6–8 mm: Slabs, stirrups, rings, and secondary reinforcement

- 10–12 mm: Beams, slabs, residential columns

- 16–20 mm: Main columns, foundations, heavy beams

- 25–40 mm: Bridges, flyovers, dams, and heavy infrastructure